What should be done when a pump is idling?

Causes of idling in centrifugal pumps:

The medium at the inlet of the pump is insufficient or the inlet pressure is too low, or the inlet pipeline of the pump is blocked, or the air in the pump chamber has not been completely discharged.

Hazards

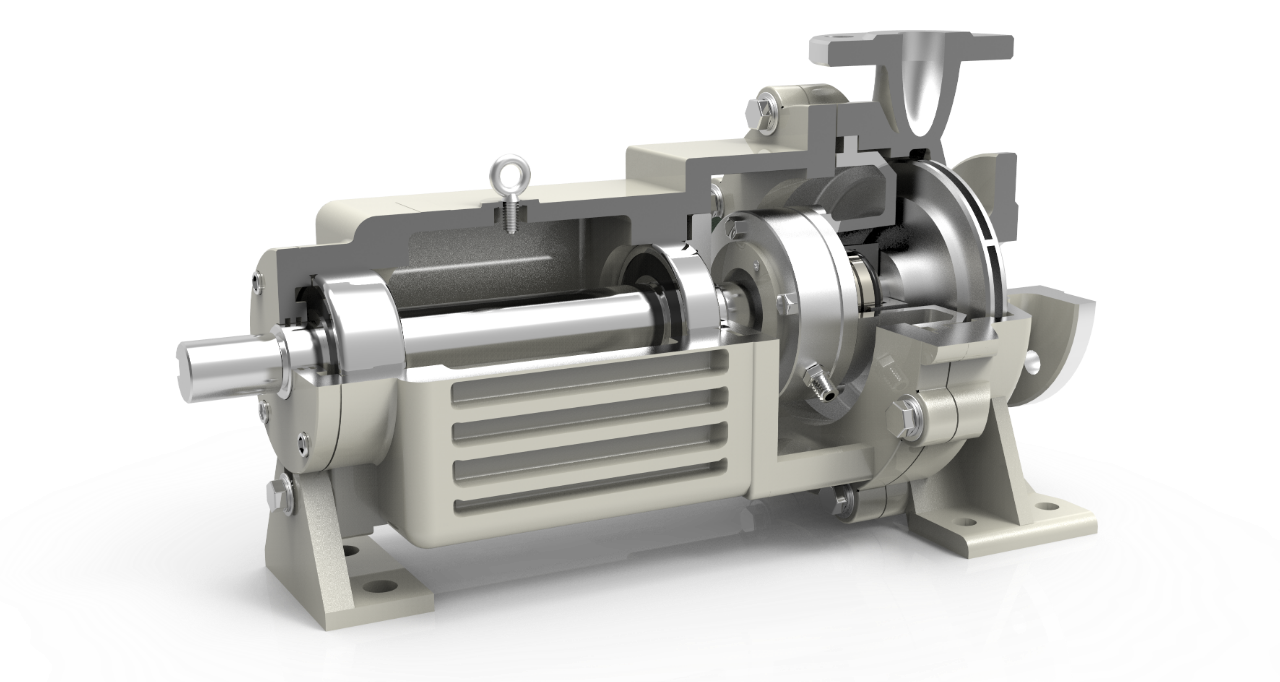

When a centrifugal pump is idling, the impeller does not contact or contacts very little with the medium, and cannot work effectively. The liquid cannot be transported normally, which is all doing useless work. Since there is no effective work being done, the load on the motor is very small, and the generated current is also small, so there is no significant impact on the motor. However, idling has a fatal impact on the pump.

An idling pump is prone to cavitation, causing damage to the pump body and flow-through components;

Whether it is a mechanical seal or a packing seal form for an idling pump, without the lubrication of the liquid, dry grinding will occur, resulting in rapid damage;

The rotor components and pump body of an idling pump will heat up. Without the cooling effect of the liquid, due to thermal expansion and contraction, those narrow clearance positions (such as the sealing ring) are very likely to seize;

For a multi-stage centrifugal pump that is idling, the balance disc has no lubrication from the liquid, and the balance disc will soon be burned out and damaged.

Prevention and Recommendations

01 Clearance Treatment

Treat each clearance position of the centrifugal pump. Expand it under permissible conditions to prevent seizing;

02 Pump Shaft Treatment

Perform special processes such as quenching and tempering, heat treatment, etc. on the shaft of the centrifugal pump to increase its hardness. Use materials with low flexibility to prevent significant swinging and seizing during idling;

03 Seal Treatment

Use a mechanical seal or packing cavity that does not rely on liquid medium for lubrication;

04 Bearing Treatment

Select a sealed, self-lubricating bearing that does not require oiling.

Recommendations

The pump chamber of a horizontal self-priming centrifugal pump has a relatively larger volume space compared to other centrifugal pumps, and there is a position that can store water. Before the normal operation of the self-priming centrifugal pump, the chamber should be filled with liquid. During the startup phase, there is a period of self-priming time during which air is continuously discharged out of the pump body. This period belongs to partial idling.

Set up an idling sensing system. Use modern equipment to monitor the water pump in real-time. When the centrifugal pump idles, immediately sound an alarm and automatically shut down to protect the safety of the unit.